Starting a mechanic business requires a lot of hard work, dedication and a strong foundation of tools. Without the proper equipment, even the most skilled mechanic won’t be able to perform their job effectively.

In this article, we’ll take a look at the essential tools that every mechanic needs to start their business and provide their customers with top-notch service. From the basics like wrenches and sockets to more specialized equipment like transmission jacks and spring compressors, we’ll cover everything you need to know to get your business up and running.

Why are professional car mechanic tools important in business?

Having the right tools is essential for any professional mechanic who wants to start their own business. Proper tools help mechanics perform their tasks with precision, speed and efficiency, which ultimately leads to higher customer satisfaction and a better reputation for the business. Here are five reasons why tools are important to mechanics:

- Accuracy – Using the correct tool for a job ensures accurate and precise work. Accurate workmanship enhances customer trust and satisfaction, and it reduces the likelihood of costly rework.

- Efficiency – Proper tools allow mechanics to complete jobs quickly and efficiently, which helps increase the number of jobs a mechanic can handle in a day.

- Safety – The right tools help keep mechanics safe on the job, reducing the risk of accidents or injuries. This is especially important in high-risk environments like engine repair, where the wrong tool or technique can lead to serious harm.

- Professionalism – A mechanic with the right tools conveys professionalism and expertise. This helps build trust and confidence with customers.

- Longevity – High-quality tools last longer and require less maintenance, which means they will save money in the long run. Additionally, a mechanic who invests in quality tools will enjoy a longer lifespan for their business.

Must-Have Mechanics Tools

The must-have tools for professional mechanics include socket sets, wrenches, screwdrivers and pliers, among others. These tools allow mechanics to perform routine maintenance and repairs on vehicles efficiently and accurately, ensuring that all components are in good working order. With the right tools, mechanics can work more safely and productively, delivering better results to their clients.

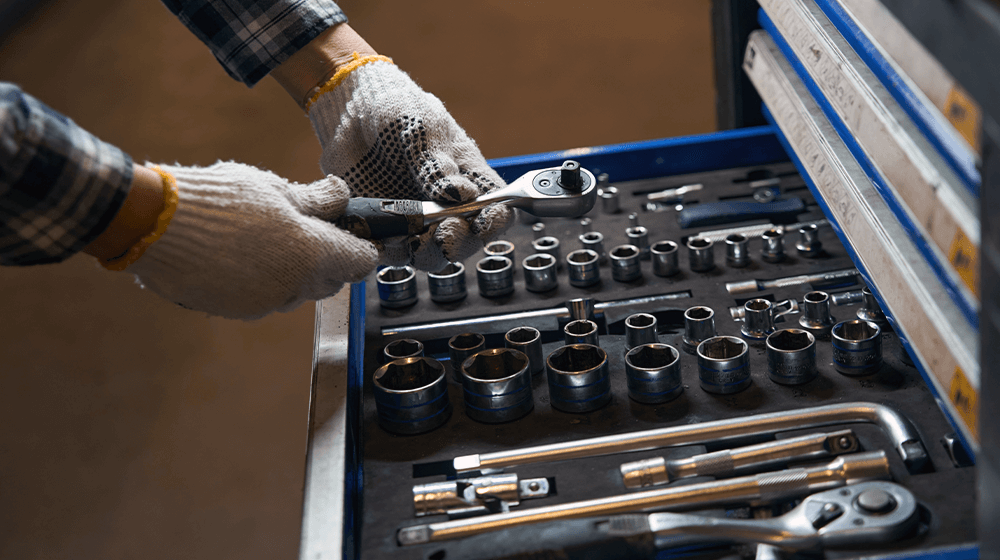

Socket Set

Socket sets and socket wrenches are vital tools for professional mechanics, and they consist of various socket sizes and attachments that fit over nuts and bolts. Socket wrenches allow mechanics to work more efficiently and effectively, accessing and tightening or loosening fasteners in hard-to-reach areas.

- Standard sockets – Standard sockets, consisting of a metal cylinder with a hexagonal opening on one end that fits over a nut or bolt head, are a basic tool for mechanics. They come in various sizes to fit different nuts and bolts and are used with a ratchet wrench or breaker bar to tighten or loosen fasteners. A mechanic needs standard sockets to perform routine maintenance and repairs on cars, making them an essential tool in any mechanic’s toolbox.

- Deep sockets – Deep sockets are similar to standard sockets but have a longer length, making them ideal for reaching fasteners in tight or recessed spaces. They allow mechanics to access bolts that are set deep into the engine bay or undercarriage, where a standard socket cannot reach. A mechanic needs deep sockets to work efficiently and effectively on various parts of a car, ensuring that all components are maintained correctly.

- Impact sockets – Impact sockets are designed to withstand the high torque generated by impact wrenches used to remove stubborn or rusted bolts. They are made of high-strength materials such as chrome molybdenum and have a thicker wall than standard sockets. A mechanic needs impact sockets to perform heavy-duty repairs, such as suspension or engine work, where high torque is required to loosen or tighten bolts. Using the right tool ensures the job is done correctly and reduces the risk of damaging components or causing accidents.

- Torx sockets – Torx sockets are a specialized tool used to remove and install Torx screws and bolts, which have a star-shaped pattern on the head. They come in different sizes to fit various Torx screws and bolts used in modern cars and equipment. A mechanic needs Torx sockets to work on engines, transmissions and electrical systems, where Torx fasteners are commonly used. Using the right tool ensures that the fasteners are tightened or loosened correctly, reducing the risk of damaging components or causing accidents.

- Spark plug sockets – Spark plug sockets are specialized tools used to remove and install spark plugs. They have a rubber insert that holds the spark plug securely, preventing it from falling into the engine bay. They come in a range of sizes, depending on the spark plug used in the engine. A mechanic needs spark plug sockets to perform routine maintenance on a vehicle’s ignition system, ensuring that the engine runs smoothly and efficiently. Using the right tool also reduces the risk of damaging the spark plug or other engine components during the maintenance process.

Wrenches

Wrenches are an essential tool for professional mechanics, used to tighten or loosen bolts and nuts. They come in various sizes and types, including combination, adjustable, and torque wrenches, and they are a must-have for any mechanic’s toolbox.

- Combination wrenches – A combination wrench is a versatile hand tool with an open-end wrench on one side and a box-end wrench on the other. Its ability to work on both hexagonal and square-shaped nuts and bolts makes it an indispensable tool for any mechanic. With a range of sizes available, a combination wrench allows mechanics to easily work on different types of fasteners and in tight spaces, making it a must-have in any professional mechanic’s toolbox.

- Ratcheting wrenches – Ratcheting wrenches allow for continuous rotation in one direction, making it easier and quicker to tighten or loosen fasteners. They are especially useful in tight spaces where a regular wrench would require constant repositioning.

- Torque wrenches – A torque wrench is a precision hand tool that measures the amount of force or torque being applied to a fastener during tightening. It is essential for mechanics as it ensures that bolts and nuts are tightened to the manufacturer’s specified torque settings, which is critical for safety and performance. A torque wrench is especially useful for engine and transmission work, suspension, and brake systems.

- Adjustable wrenches – An adjustable wrench, also known as a crescent wrench, is a versatile hand tool that features an adjustable jaw that can be used to fit different-sized nuts and bolts. It is essential for mechanics as it allows them to work on fasteners of different sizes without needing multiple wrenches. An adjustable wrench is useful for many repair jobs, making it an essential tool for any professional mechanic’s toolbox.

- Pipe wrenches – A pipe wrench is a heavy-duty hand tool that is used to grip, tighten and loosen pipes and fittings. It features an adjustable jaw that can be expanded or contracted to fit around different pipe diameters. A pipe wrench is essential for mechanics who work on plumbing or automotive exhaust systems, as it provides a strong grip and leverage to turn stubborn fittings.

Pliers

Pliers are a versatile tool for professional mechanics, used for gripping, cutting and bending wires, hoses and other components. They come in various sizes and types, including needle-nose, locking and cutting pliers, and are a must-have for any mechanic’s toolbox.

- Needle-nose pliers – Needle-nose pliers are a type of pliers with long, slender jaws that taper to a point, allowing them to reach into tight spaces and grasp small objects with precision. They are essential for mechanics as they are versatile tools that can be used for a wide range of tasks, including electrical work, removing fuses and bending wire. Needle-nose pliers are an essential tool for any professional mechanic’s toolbox.

- Diagonal cutting pliers – Diagonal cutting pliers, also known as wire cutters, are a type of cutting tool that features angled jaws that cut wire and other materials at an angle. They are essential for mechanics as they can cut through a wide range of materials with precision, including wires, cables and hoses. Diagonal cutting pliers are useful for a range of tasks, making them an indispensable tool for any professional mechanic’s toolbox.

- Slip-joint pliers – Slip-joint pliers are a type of hand tool that features an adjustable pivot point, allowing the jaws to open and close to grip objects of varying sizes. They are essential for mechanics as they can be used for a wide range of tasks, including holding and bending materials, tightening and loosening nuts and bolts, as well as removing stubborn parts. Slip-joint pliers are an indispensable tool for any professional mechanic’s toolbox.

- Channel locks – Channel locks, also known as tongue-and-groove pliers, are a type of hand tool that features an adjustable jaw that can be set to different widths. They are essential for mechanics as they can be used to grip and turn objects of varying sizes, including pipes, fittings and nuts. Channel locks are useful for a wide range of repair tasks, making them an indispensable tool for any professional mechanic’s toolbox.

- Locking pliers (Vise-Grips) – Locking pliers, also known as Vise-Grips, are a type of hand tool that features a locking mechanism that allows the jaws to clamp onto an object and hold it securely in place. They are essential for mechanics as they can be used to grip and hold materials while other tasks are performed, such as cutting or drilling. Locking pliers are useful for a wide range of repair tasks, making them an indispensable tool for any professional mechanic’s toolbox.

Screwdrivers

Screwdrivers are a crucial tool for professional mechanics, used for driving screws and bolts in and out of components. They come in various sizes and types, including Phillips, flat-head and torx, and they are a must-have for any mechanic’s toolbox.

- Flathead screwdrivers – A flathead screwdriver is a hand tool with a flat, narrow tip that is used to turn screws with a single slot or groove on the head. They are essential for mechanics as screws are used in almost all types of machinery and equipment, and a flathead screwdriver is often needed to remove or tighten screws during repair or maintenance tasks. A flathead screwdriver is an indispensable tool for any professional mechanic’s toolbox.

- Phillips screwdrivers – A Phillips screwdriver is a hand tool with a pointed tip that is shaped like a cross, designed to fit into screws with a corresponding cross-shaped slot on the head. They are essential for mechanics as Phillips screws are commonly used in many types of machinery and equipment, and a Phillips screwdriver is often needed to remove or tighten these screws during repair or maintenance tasks. A Phillips screwdriver is an indispensable tool for any professional mechanic’s toolbox.

- Torx screwdrivers – A Torx screwdriver is a hand tool with a six-pointed star-shaped tip designed to fit into screws with a corresponding star-shaped slot on the head. They are essential for mechanics as Torx screws are commonly used in automotive, electronics and industrial equipment, and a Torx screwdriver is often needed to remove or tighten these screws during repair or maintenance tasks. A Torx screwdriver is an indispensable tool for any professional mechanic’s toolbox, especially for those who work on cars or machinery with Torx screws.

Hammers and Mallets

Hammers and mallets are essential tools for professional mechanics, used for striking and shaping components. They come in various sizes and types, including ball-peen, dead blow and rubber mallets, and they are a must-have for any mechanic’s toolbox.

- Ball-peen hammers – A ball-peen hammer is a hand tool with a rounded head on one end and a flat striking surface on the other. It is used for striking or shaping metal objects and is an essential tool for mechanics. It is particularly useful for shaping and forming metal parts or for removing and setting rivets. A ball-peen hammer is a versatile tool that every professional mechanic should have in their toolbox.

- Rubber mallets: A rubber mallet is a hand tool with a rubber head that is used for striking and shaping objects that could be damaged by metal hammers. It is an essential tool for mechanics, as it is often used for tapping parts into place or adjusting components without causing damage. A rubber mallet is a useful tool for a wide range of repair and maintenance tasks, making it a must-have in any professional mechanic’s toolbox.

- Dead blow hammers – A dead blow hammer is a hand tool that features a hollow head filled with sand or steel shot. This design minimizes rebound and shock, which allows the hammer to deliver a controlled strike that won’t damage the surrounding area. It is an essential tool for mechanics who need to strike objects without causing damage or leaving marks. The dead blow hammer is useful for a wide range of tasks, from driving nails to tapping parts into place, making it a must-have tool for any professional mechanic.

Pry Bars

Pry bars are an essential tool for professional mechanics, used for prying, lifting, and aligning components. They come in various sizes and types, including flat bars, crowbars and pinch bars, and they are a must-have for any mechanic’s toolbox.

- Flat pry bars – A flat pry bar, also known as a flat bar, is a long, flat, and tapered tool used to separate and lift objects. It’s an essential tool for mechanics, as it’s used for a variety of tasks, including removing stubborn nails, prying apart glued parts and loosening rusted bolts. It can also be used to lever or position heavy objects, making it a versatile tool for any mechanic’s toolbox.

- Crowbars – A crowbar is a tool consisting of a metal bar with a flattened end and a curved end. It is typically used to pry and leverage objects apart. The curved end is useful for applying leverage, while the flattened end can be used to strike objects. Mechanics may need a crowbar for various tasks, such as removing stubborn parts or separating stuck components.

- Wonder bars – A wonder bar is a long, flat and thin pry bar that is designed to be versatile and useful in a variety of applications. It is commonly used for prying, lifting and separating objects during automotive repair and maintenance tasks. Its thin and flat shape allows it to easily fit into tight spaces and exert force in a precise manner. Mechanics need a wonder bar as it is an essential tool for removing parts that are stuck or difficult to access.

- Pinch bar – A pinch bar, also known as a pry bar or wrecking bar, is a long and sturdy metal bar with a pointed end on one side and a flattened end on the other. It is used to pry, lift and move heavy objects. The pointed end is used to get under and lift objects, while the flattened end is used for leverage. A mechanic needs a pinch bar to remove stubborn parts or pry apart tight-fitting components, making it an essential tool in any mechanic’s arsenal.

Power Tools

Power tools are a valuable addition to any professional mechanic’s toolkit, providing the ability to work faster and more efficiently. Examples include impact wrenches, drills and air compressors, all of which help hasten repairs and maintenance tasks.

Impact Wrench

Impact wrenches are a must-have power tool for professional mechanics, providing high-torque output to quickly tighten or loosen bolts and nuts. They come in various sizes and types, including corded and cordless models, and they are essential for fast-paced repair work.

- Cordless impact wrenches – A cordless impact wrench is a battery-powered tool that delivers high torque output for quickly tightening or loosening bolts and nuts. It provides the convenience of portability and freedom of movement without being tethered to an electrical outlet or air compressor. A mechanic needs a cordless impact wrench for fast and efficient work on various types of cars, heavy equipment and machinery.

- Air impact wrenches – An air impact wrench, is a pneumatic tool used to tighten or loosen bolts and nuts. It is powered by compressed air and can deliver high torque output, making it a crucial tool for automotive and industrial applications. With its ability to quickly remove stubborn nuts and bolts, a mechanic can save significant time and effort during repairs, making it an essential tool in any mechanic’s toolbox.

- Hydraulic impact wrench – A hydraulic wrench is a powerful tool used to tighten or loosen bolts and nuts to a specific torque value. It works by using hydraulic pressure to apply the necessary force to achieve the desired torque setting. Professional mechanics often use hydraulic wrenches when working with heavy-duty equipment and machinery, as they provide accurate and consistent results with minimal effort. It is an essential tool for any mechanic who deals with large bolts and nuts regularly.

Air Compressor

Air compressors are a versatile power tool for professional mechanics, providing a source of compressed air for use with impact wrenches, air hammers and other pneumatic tools. They come in various sizes and types, including portable and stationary models, and they are a must-have for any busy mechanic’s workshop.

- Portable air compressors – A portable air compressor is a small and compact air compressor that can be easily transported and used at different job sites. It typically runs on electricity and can be used to power air tools such as impact wrenches, pneumatic hammers and spray guns. It is an essential tool for mechanics as it provides a source of compressed air that is necessary for many tasks in automotive repair and maintenance, such as inflating tires and operating pneumatic tools.

- Stationary air compressors – A stationary air compressor is a large-sized compressor that is permanently installed in a garage or shop. It has a high capacity and provides a continuous flow of compressed air for extended periods. This tool is necessary for mechanics who require a high volume of compressed air for various applications, such as powering air tools, filling tires and painting vehicles. A stationary air compressor can also be used in industrial settings that require consistent and reliable compressed air.

- Two-stage compressors – A two-stage compressor is a type of air compressor that uses two separate cylinders to compress air. In the first stage, air is compressed to an intermediate pressure and then it’s further compressed in the second stage to the final pressure. This results in higher output pressures and increased efficiency. Mechanics often need this type of compressor for heavy-duty applications, such as operating large air tools or powering pneumatic machines.

Electric Drills

Electric drills are an essential power tool for professional mechanics, used for drilling holes, tapping threads and driving screws. They come in various sizes and types, including corded and cordless models, and they are a must-have for any workshop.

- Corded drills – A corded drill is an electric drill powered by an electric cord plugged into an outlet. It is an essential tool for a mechanic as it provides consistent and reliable power without the need for charging or battery replacement. Corded drills also typically have higher torque and speed capabilities compared to cordless models, making them ideal for heavy-duty tasks such as drilling through metal or concrete.

- Cordless drills – A cordless drill, also known as a battery-powered drill, is a handheld power tool that uses rechargeable batteries to operate. It offers the flexibility and convenience of being able to move around freely without being tethered to a power outlet. A mechanic needs a cordless drill to perform drilling, driving, and fastening tasks quickly and efficiently, especially in hard-to-reach areas or on-the-go situations. It can also come in handy for disassembling and reassembling various mechanical parts.

- Hammer drills – A hammer drill is a power tool that combines rotary drilling with a hammering action to enable the user to drill through hard surfaces like concrete, brick, and stone. Its hammering action delivers rapid, short, and powerful blows to the workpiece, making it ideal for drilling into tough materials. A mechanic may need a hammer drill to create holes in concrete or masonry surfaces for the installation of anchors or to create access points for routing electrical or plumbing lines.

- Right-angle drills – A right-angle drill, also known as a corner drill, is a type of electric drill designed with a compact head and a 90-degree angled chuck. This design allows the drill to access tight spaces and corners that a regular drill cannot reach. Mechanics often use a right-angle drill for drilling in hard-to-reach areas of a car or machinery. It is an essential tool for performing tasks such as installing wiring, plumbing, and HVAC systems.

Angle Grinder

Angle grinders are a versatile power tool for professional mechanics, used for cutting, grinding and polishing metal and other materials. They come in various sizes and types, including corded and cordless models, and they are essential for tasks such as removing rust and smoothing welds.

- Cordless angle grinder – A cordless angle grinder is a portable, battery-operated tool that is used for cutting, grinding and polishing metal and other materials. It is a versatile tool that can be used in tight spaces where corded grinders cannot reach, and it eliminates the need for a power outlet. Mechanics often need to work in different locations and positions, and a cordless angle grinder can provide them with the flexibility and convenience they need to get the job done efficiently.

- Electric angle grinder – An electric angle grinder is a handheld power tool that uses an abrasive disc to grind, cut or polish different materials such as metal, stone and concrete. The motor in an electric angle grinder spins the disc at high speeds, enabling the user to remove material quickly and efficiently. Professional mechanics need an electric angle grinder to perform a variety of tasks such as removing rust and paint, cutting and shaping metal, and preparing surfaces for welding or painting.

- Pneumatic angle grinder – A pneumatic angle grinder, also known as an air grinder, is a handheld power tool that uses compressed air to drive its motor, which spins an abrasive disc for cutting, grinding, and polishing. Mechanics need a pneumatic angle grinder because it is powerful, durable, and lightweight, making it ideal for heavy-duty tasks in metalworking, fabrication, and construction. The compressed air power source also eliminates the need for an electrical outlet, making it a versatile and portable tool for various job sites.

Air Ratchet

Air ratchets are a handy power tool for professional mechanics, used for quickly removing and tightening bolts and nuts. They come in various sizes and are ideal for tasks in tight spaces, making them an essential tool for any busy mechanic’s workshop.

- Pistol grip air ratchet – A pistol grip air ratchet is a type of pneumatic tool that is designed to quickly remove and install bolts and fasteners. It is named for its shape, which resembles that of a handgun grip and is operated by compressed air. The compact size and high torque of a pistol grip air ratchet make it an essential tool for any mechanic, allowing them to access tight spaces and quickly loosen or tighten fasteners with ease.

- Inline air ratchet – An inline grip air ratchet is a type of air-powered ratchet with a slim and elongated design, allowing for better access to tight spaces. This tool is particularly useful for working on engines, where space can be limited. The inline grip design also provides improved balance and control, allowing for better precision and less fatigue during extended use. A mechanic may need an inline grip air ratchet to efficiently and effectively perform maintenance and repairs on vehicles.

- Flex-head air ratchet – A flex-head air ratchet is a type of air ratchet that has a flexible head, allowing it to reach tight and difficult-to-access areas. It is an essential tool for mechanics who need to work on engines, suspension systems, and other parts of a vehicle or machinery. The flex-head feature provides added versatility and maneuverability, allowing mechanics to work efficiently and effectively.

Diagnostic Tools

Diagnostic tools are essential for professional mechanics, allowing them to quickly identify and fix problems with a vehicle’s engine and other systems. These tools include code readers, scan tools and oscilloscopes, and they are critical for accurate and efficient repairs.

OBD-II Scanner

An OBD-II scanner is a must-have diagnostic tool for any professional mechanic. It allows you to read and clear engine codes, monitor real-time data and perform other essential functions to quickly identify and diagnose vehicle problems.

- Basic code reader – A basic code reader is a diagnostic tool that connects to a vehicle’s onboard computer system and reads error codes related to engine and emissions systems. Mechanics need this tool to quickly and accurately identify the root cause of a vehicle’s problem, enabling them to make efficient and effective repairs. This tool is essential for any mechanic looking to provide high-quality automotive repair services.

- DIY scanner – A DIY scanner is a handheld diagnostic tool that allows a mechanic to access and interpret a vehicle’s diagnostic codes. It is an affordable alternative to more expensive professional-grade scanners, and it is user-friendly and portable. Mechanics need this tool to quickly and accurately diagnose common problems in a wide range of vehicles, providing a cost-effective solution for their customers. The DIY scanner is an essential tool for any mechanic looking to start their own business.

- Professional diagnostic tool – A professional diagnostics tool is an advanced diagnostic device that is designed to read and analyze data from a vehicle’s onboard computer system. It provides a detailed analysis of the vehicle’s performance, including engine, transmission and other systems. Professional mechanics need this tool to diagnose complex problems and identify issues that may not be apparent with a basic code reader or DIY scanner. It is an essential tool for any mechanic looking to provide high-quality and comprehensive automotive repair services.

Multimeter

A multimeter is an essential diagnostic tool for mechanics as it can measure voltage, current and resistance in electrical systems. It’s necessary to diagnose and troubleshoot issues in a vehicle’s electrical system, including battery and charging system problems, circuit faults and sensor issues.

- Digital multimeter – A digital multimeter (DMM) is a basic electrical testing tool that measures voltage, current and resistance. It is essential for professional mechanics as it allows them to diagnose and troubleshoot a wide range of electrical problems in vehicles, from checking battery voltage to testing sensors and circuits. The DMM is an essential tool for any mechanic looking to provide comprehensive and accurate automotive repair services.

- Fluke multimeter – A Fluke multimeter is a high-quality and accurate electrical testing tool that can measure voltage, current, resistance, capacitance and frequency, among other things. It is essential for professional mechanics who need to perform advanced electrical work and require precise measurements. Fluke multimeters are durable and reliable, and they come with a range of features that make them indispensable tools for any mechanic looking to provide high-quality automotive repair services.

- Automotive multimeter – An automotive multimeter is a specialized testing tool designed specifically for automotive work. It can measure AC/DC voltage, current, resistance, and temperature, making it an essential tool for diagnosing electrical problems in vehicles. With features such as min/max/avg recording and a backlit display, automotive multimeters are indispensable tools for professional mechanics looking to provide accurate and efficient automotive repair services.

Test Lights

Test lights are handheld tools that allow mechanics to check for electrical issues. They are designed to illuminate when they come into contact with a live electrical circuit, providing an indication of the presence of voltage. Test lights are essential tools for any mechanic who needs to troubleshoot electrical problems in vehicles.

- Circuit tester – A circuit tester is a basic test light tool that is used to check for the presence of voltage in a circuit. It is an essential tool for professional mechanics as it allows them to diagnose and troubleshoot electrical problems in vehicles quickly and accurately. With a circuit tester, mechanics can test fuses, switches, relays and other components, making it an indispensable tool for any mechanic looking to provide comprehensive and efficient automotive repair services.

- Power probe – A power probe is a versatile and advanced test light tool that is essential for professional mechanics who need to diagnose and troubleshoot complex electrical problems in vehicles. It can test voltage, resistance and continuity, and it has the ability to power up components directly for testing purposes. With its advanced features, a power probe is an indispensable tool for any mechanic looking to provide high-quality and accurate automotive repair services.

- LED test light – An LED test light is a specialized test light that uses LEDs to indicate the presence of voltage in a circuit. It is more durable and reliable than traditional test lights, and it is an essential tool for professional mechanics who work in low-light conditions or in areas with poor visibility. With its bright and visible LEDs, an LED test light allows mechanics to quickly and easily test circuits, making it an indispensable tool for any mechanic looking to provide efficient and accurate automotive repair services.

Vacuum and Pressure Gauges

Vacuum gauges and pressure gauges are essential tools for a mechanic to accurately diagnose engine problems. They measure the pressure and vacuum in different parts of the engine, helping to detect leaks and other issues that affect engine performance.

- Fuel Pressure gauge – A fuel pressure gauge is a specialized tool used by professional mechanics to measure the pressure of the fuel system in a vehicle. It is an essential tool for diagnosing fuel system problems such as low fuel pressure, fuel pump failure, or a faulty fuel pressure regulator. With a fuel pressure gauge, mechanics can accurately and quickly diagnose fuel system issues, making it an indispensable tool for any mechanic looking to provide comprehensive and efficient automotive repair services.

- Compression gauge – A compression gauge is a specialized tool used by professional mechanics to measure the compression in the cylinders of an engine. It is an essential tool for diagnosing engine problems such as worn piston rings, damaged valves, or a blown head gasket. With a compression gauge, mechanics can accurately and quickly diagnose engine issues, making it an indispensable tool for any mechanic looking to provide comprehensive and efficient automotive repair services.

- Vacuum gauge – A vacuum gauge is a specialized tool used by professional mechanics to measure the amount of vacuum pressure in a vehicle’s engine. It is used to diagnose a wide range of engine problems such as leaks in the intake manifold or vacuum lines, clogged air filters or a faulty PCV valve. With a vacuum gauge, mechanics can accurately and quickly diagnose engine issues, making it an indispensable tool for any mechanic looking to provide comprehensive and efficient automotive repair services.

Specialty Tools

Specialty tools are critical for a mechanic to tackle complex automotive repairs. Brake tools help with brake pad replacement, transmission tools for transmission work, suspension and steering tools for alignment and suspension work, and engine tools for tasks like valve adjustments and timing belt replacements.

Brake Tools

Brake tools are essential for any mechanic working on automotive braking systems. They include brake caliper tools, brake bleeder kits and brake piston compressors, which allow for safe and efficient brake maintenance and repairs.

- Brake bleeders – A brake bleeder is a specialized tool used by professional mechanics to remove air bubbles from the brake lines of a vehicle. When air bubbles are present in the brake lines, it can lead to spongy brakes and reduced stopping power, making it an essential tool for ensuring optimal brake performance and safety. With a brake bleeder, mechanics can quickly and efficiently remove air bubbles, ensuring that the brakes are working properly and providing peace of mind to their customers.

- Brake caliper tools – A brake caliper tool is a specialized tool used by professional mechanics to service and repair brake calipers. It is designed to compress the brake caliper pistons, making it easier to replace brake pads or service the caliper assembly. With a brake caliper tool, mechanics can quickly and safely compress the pistons, ensuring that the brakes are functioning properly and providing their customers with reliable and safe vehicles.

- Brake line tools – A brake line tool is a specialized tool used by professional mechanics to remove and replace brake lines. It is designed to grip and hold the brake line while the mechanic loosens or tightens the fittings. With a brake line tool, mechanics can work efficiently and safely, avoiding damage to the brake lines and ensuring that the brake system is operating properly. It is an essential tool for any mechanic working on brake systems.

Transmission Tools

Transmission tools are necessary for any mechanic that works on automatic or manual transmissions. These tools include transmission jacks, fluid extractors and specialty wrenches to properly service and maintain the transmission.

- Transmission jacks – A transmission jack is a specialized lifting device that is designed to support and move heavy automotive transmissions during repair or replacement. It features a wide base, adjustable arms and a hydraulic lifting mechanism that allows mechanics to safely and easily raise and lower heavy transmissions. It is an essential tool for any mechanic working on transmissions and helps to prevent injury and damage to the vehicle.

- Clutch alignment tools – A clutch alignment tool is a device used to align the clutch disc with the pressure plate during installation. The tool ensures that the clutch is centered properly, which prevents premature wear and damage to the clutch components. Professional mechanics need this tool to ensure a proper clutch installation, which is essential for the safe and efficient operation of a vehicle.

- Fluid exchange tools – Fluid exchange tools are used by mechanics to flush out and replace fluids such as coolant, transmission fluid and brake fluid in a vehicle. These tools use a vacuum or pressure system to remove old fluid and replace it with new fluid, ensuring that the vehicle’s fluids are clean and at the correct level. Fluid exchange tools are essential for maintaining the health and longevity of a vehicle’s various systems, making them an important investment for any mechanic’s business.

Suspension and Steering Tools

Suspension and steering tools are essential for a mechanic’s business. They include ball joint separators, tie rod end pullers and spring compressors, necessary for repairing suspension and steering systems.

- Ball joint separators – A ball joint separator, also known as a pickle fork, is a tool used to separate the ball joint from the steering knuckle or control arm. This tool is essential for performing suspension repairs and replacements, as it allows for the safe removal and installation of ball joints without damaging the surrounding components. It saves time and prevents unnecessary costs associated with replacing damaged parts.

- Tie rod tools – Tie rod tools are essential for any mechanic performing steering or suspension work on vehicles. They are designed to safely remove and install tie rods, which are crucial components that connect the steering rack to the wheels. Tie rod tools come in various shapes and sizes and can be used to remove tie rod ends without damaging them, making them a must-have tool for any professional mechanic.

- Spring compressors – A spring compressor is a tool that is used to compress coil springs, allowing them to be safely removed or installed in a vehicle’s suspension system. This tool is important for mechanics because it allows them to work on the suspension system without risking injury or damage to the vehicle. Without a spring compressor, it can be difficult or even dangerous to remove or install coil springs.

Engine Tools

Engine tools are essential for professional mechanics, including compression testers, torque wrenches, valve spring compressors and timing lights. These tools ensure precise engine diagnosis, repair and maintenance.

- Timing lights – A timing light is a specialized tool used by mechanics to precisely set the timing on an engine. It works by illuminating a timing mark on the engine’s crankshaft pulley with a bright strobe light, allowing the mechanic to precisely adjust the ignition timing to the manufacturer’s specifications. A timing light is an essential tool for any mechanic who works on internal combustion engines, as proper timing is crucial to ensure optimal engine performance and efficiency.

- Compression testers – A compression tester is a tool used to measure the compression pressure of an engine cylinder. It consists of a gauge, a hose and a threaded tip that fits into the spark plug hole of the cylinder. Mechanics use compression testers to diagnose engine problems, such as worn piston rings or leaky valves, by comparing the compression readings across all cylinders. This tool is essential for engine troubleshooting and can save a mechanic time and money by pinpointing the issue quickly and accurately.

- Cylinder leak-down testers – A cylinder leak-down compressor is a tool that helps diagnose engine problems by measuring the amount of air that escapes from the combustion chamber. This tool is used to check the health of the engine’s piston rings, valves, and head gasket. A mechanic needs this tool because it provides an accurate assessment of the engine’s condition and helps identify potential issues that may affect engine performance.

Organization and Safety

Organization and safety are crucial for any mechanic’s business. Proper tool storage, labeling, and maintenance are essential for efficiency and safety. Personal protective equipment such as gloves, goggles and ear protection should always be worn.

Tool Storage Solutions

Tool storage solutions are essential for any mechanic. Toolboxes, cabinets and pegboards are popular options for storing and organizing tools. Make sure to label and categorize tools for easy access and increased productivity.

- Toolboxes – A toolbox is a storage unit that allows a mechanic to organize and store their tools. It can come in various sizes and shapes, from small portable toolboxes to larger roller cabinets. A toolbox is essential for a mechanic because it helps them keep their tools in good condition, easily accessible, and prevents them from getting lost or damaged. It also helps a mechanic maintain a clean and organized workspace, which is crucial in the automotive industry.

- Tool carts – A tool cart is a mobile storage unit designed to keep tools and equipment organized and easily accessible. It typically has multiple drawers and shelves, allowing mechanics to quickly find the tools they need without wasting time searching through a cluttered workspace. A tool cart is an essential tool for mechanics because it helps them stay organized and efficient, improving productivity and saving time.

- Pegboards and hooks – Pegboards and hooks are an efficient way to organize tools in a workshop. Pegboards are perforated boards where hooks can be inserted to hang tools, making them easily accessible and visible. These tools are crucial for mechanics as they need to have a quick and easy way to locate and access their tools to maximize efficiency and productivity. Pegboards and hooks also help in keeping the work area clean and clutter-free.

Personal Protective Equipment

Personal protective equipment (PPE) is crucial for the safety of mechanics. Essential PPE includes eye and ear protection, gloves and respirators. Choosing high-quality PPE and using it correctly can prevent accidents and injuries.

- Safety glasses – Safety glasses are a type of eye protection that are crucial for a professional mechanic. They are designed to protect the eyes from flying debris, chemicals, and other hazards that can cause eye injuries. Mechanics work with various tools and materials, and safety glasses can prevent eye injuries that could lead to serious consequences, including vision loss. Wearing safety glasses is an essential safety measure in any mechanic shop to protect the eyes from potential hazards.

- Gloves – Gloves are essential tools for professional mechanics as they protect the hands from cuts, burns, and other injuries that may result from working with various tools and machinery. Mechanics often handle sharp and hot objects, as well as chemicals and oils, which can cause skin irritation or harm. Properly fitting gloves also provide a better grip, making it easier to handle small parts or components. Overall, gloves are an important safety measure in a mechanic’s toolkit.

- Ear protection – Ear protection is an essential tool for professional mechanics that provides safety against excessive noise exposure, which can cause hearing damage or loss. These tools come in various types, such as earplugs or earmuffs, and are designed to reduce noise levels in the workplace. A mechanic needs to use ear protection regularly to prevent hearing damage and ensure a safe working environment.

What are the most important car tools for a new mechanic?

As a new mechanic starting a business, the most important tools to invest in include a comprehensive set of hand tools, air tools, diagnostic tools, specialty tools and storage solutions. Additionally, prioritizing personal protective equipment and maintaining a safe and organized workspace is crucial for success.

How much should you budget for mechanic tools when starting a business?

As a new mechanic starting a business, budgeting for tools is essential. A good rule of thumb is to budget around $10,000 to $20,000 for a basic set of essential tools, including wrenches, sockets, air tools, diagnostic tools and storage solutions. However, the budget can vary depending on the mechanic’s specialty and the size of the business.

What is the best way to organize tools in your auto repair shop?

The best way to organize tools in an auto repair shop is to use a combination of tool cabinets, pegboards and tool chests. Keep frequently used tools easily accessible and create a system for returning tools to their proper place. Regularly cleaning and maintaining tools will also help with organization.

How can you maintain your tools to ensure they last?

To ensure your tools last, always clean them after use and store them in a dry and cool place. Regularly inspect and lubricate moving parts, and keep blades and bits sharp. Use appropriate tool storage solutions and avoid exposing them to excessive heat or cold, moisture or chemicals.

Are there any mechanics tool options that are not essential but could improve efficiency?

There are several tools that are not essential, but they can improve efficiency in a mechanic’s shop. For example, a pneumatic oil extractor can help quickly and efficiently change oil. Another tool to consider is a cordless impact wrench, which can save time and reduce fatigue when removing and installing nuts and bolts.

What tools are included in mechanics tool sets?

A mechanic’s tool set typically includes a wide range of hand tools such as sockets, wrenches, pliers, screwdrivers, hammers and specialty tools like torque wrenches, impact guns, and diagnostic equipment. Some sets may also include power tools like air compressors, drills, and angle grinders. The size and variety of the set will depend on the type of work the mechanic intends to do.

Is it better to buy individual tools or a mechanic tools set?

When starting a business, purchasing mechanic tool sets can be a cost-effective way to obtain the essential tools quickly. However, individual tools allow for customization and can better suit a mechanic’s specific needs. It ultimately depends on the mechanic’s budget and personal preferences.

Read More:

Image: Envato Elements

The post originally appeared on following source : Source link